Oz Machine mašine za aluminijum i pvc

Poslednji put ažurirano 23.02.2024.

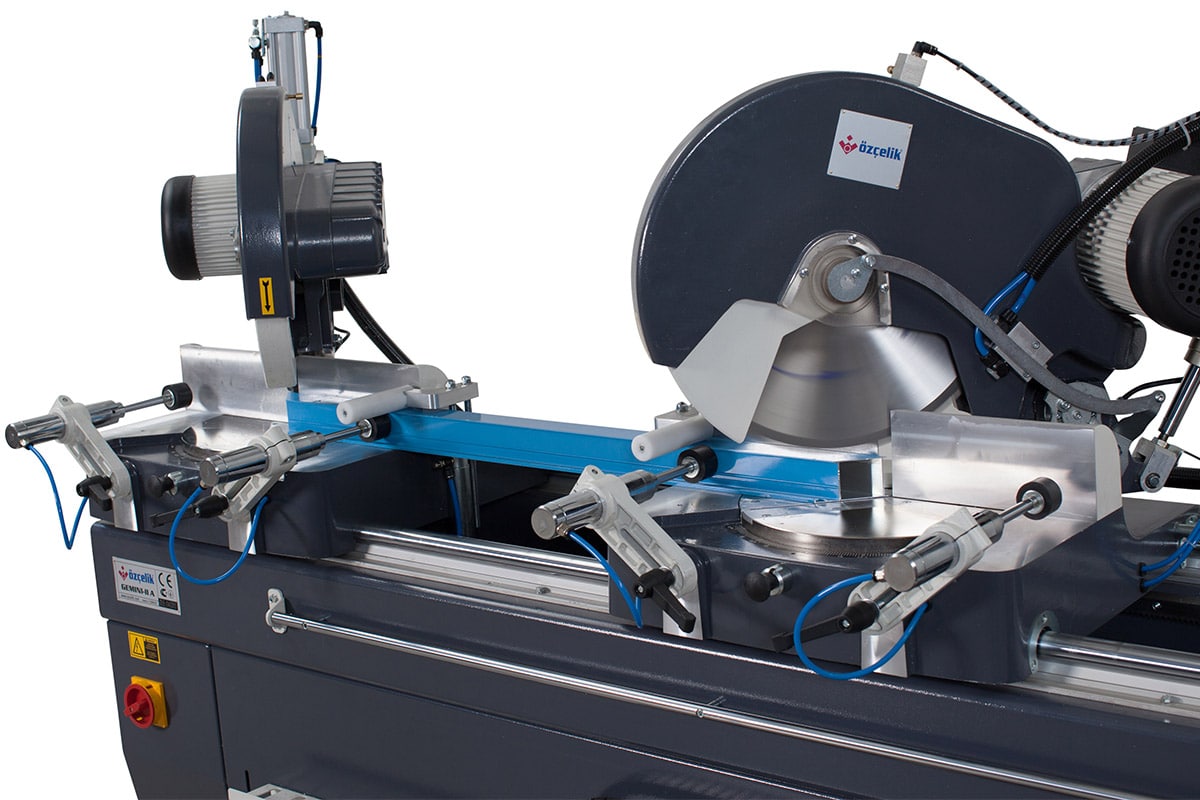

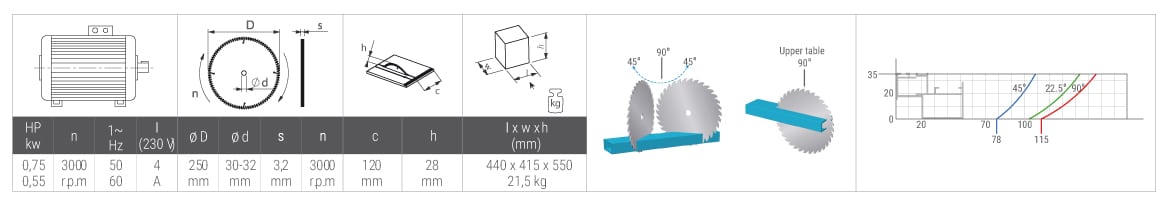

Portable Cutting Machine Ø250 mmALFAmini

FEATURES

– Used for cutting processes of aluminum, plastic and wooden materials.

– Safe cutting with double spring system and saw barrier

– 0°, 15°, 22.5°, 30°, 45° right and left angle fixing

– Ability to cut on the upper table

STANDARD EQUIPMENTS

– Profile gauge

OPTIONAL EQUIPMENTS

– Ø250 mm saw blade

– Second clamp

– Conveyor

– Stand (S – I)

GER 002

Mašina za gerovanje ALFAmini Ø250

(bez testere)

Cena sa PDV 445€

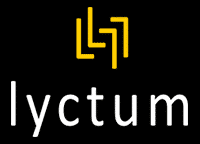

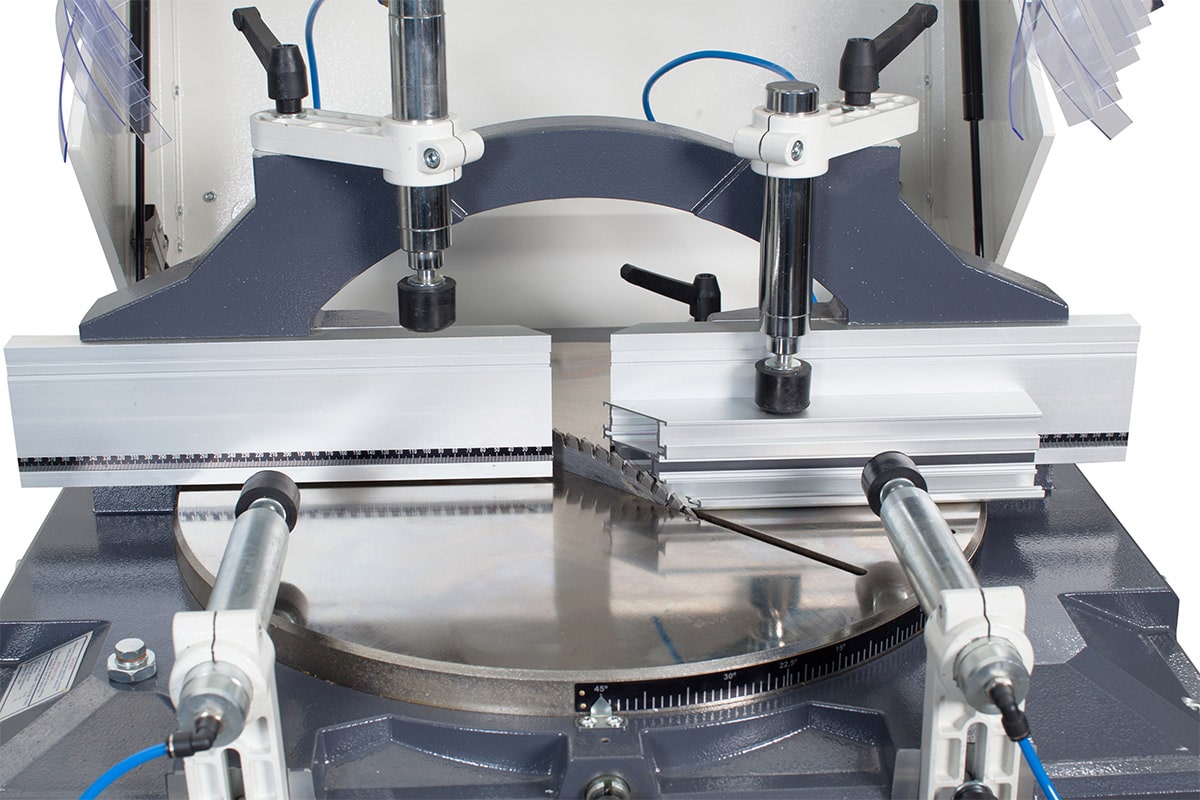

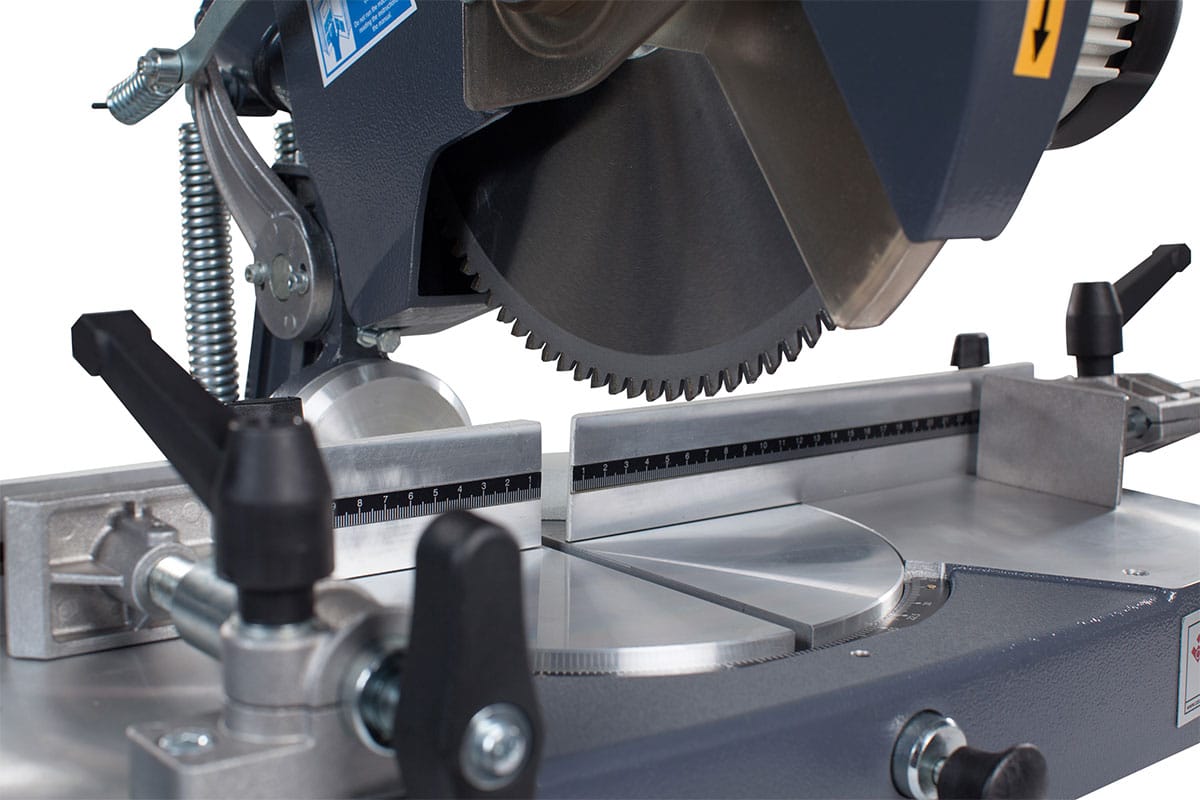

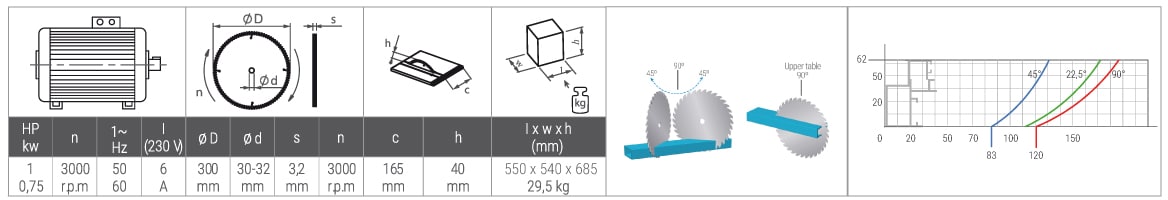

Portable Cutting Machine Ø300 mmALFA

FEATURES

– Used for cutting processes of aluminum, plastic and wooden profiles.

– Safe cutting with double spring system and saw barrier

– Cutting at any desired angle between -45° and +45°

– Ability to cut on the upper table

– 0°, 15°, 22.5°, 30°, 45° right and left angle fixing

STANDARD EQUIPMENTS

– Profile gauge

OPTIONAL EQUIPMENTS

– Ø300 mm saw blade

– Second clamp

– Conveyor

– Stand (S – I)

– Brake System

– Three-phase system

GER 001-S

Mašina za gerovanje ALFA Ø300

(bez testere)

Cena sa PDV 580€

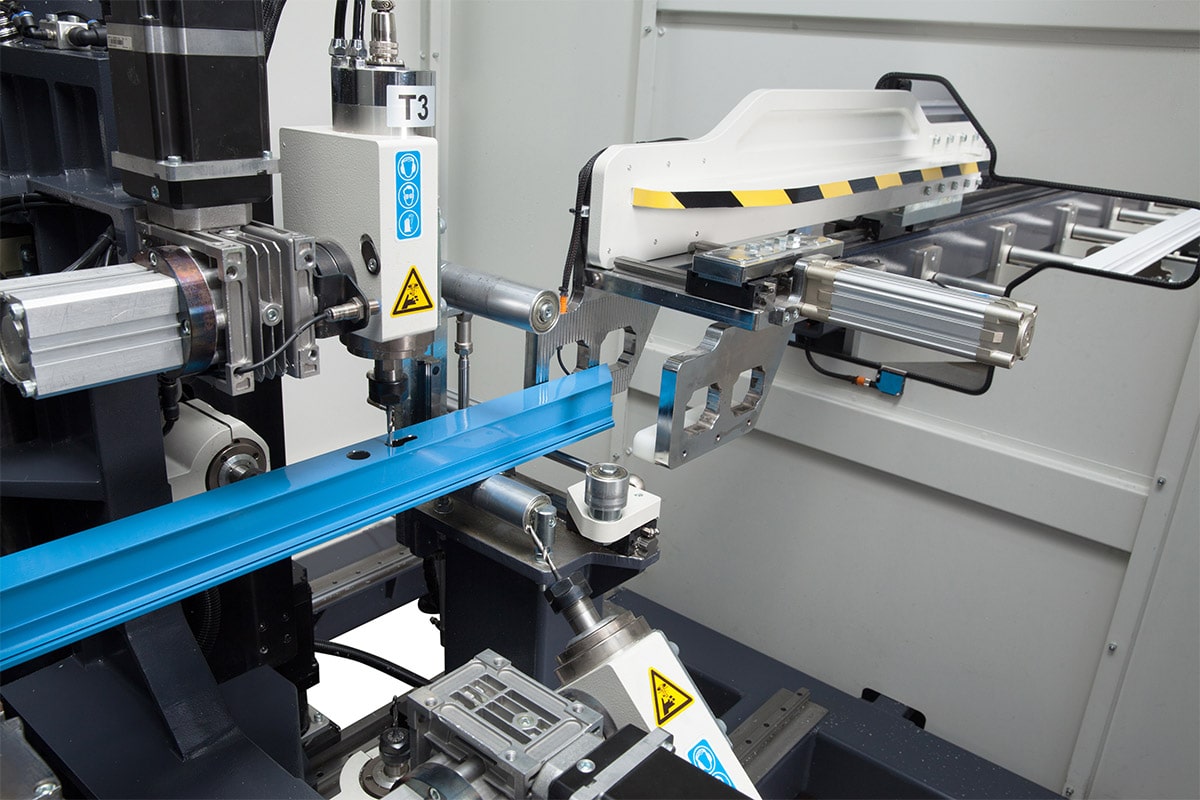

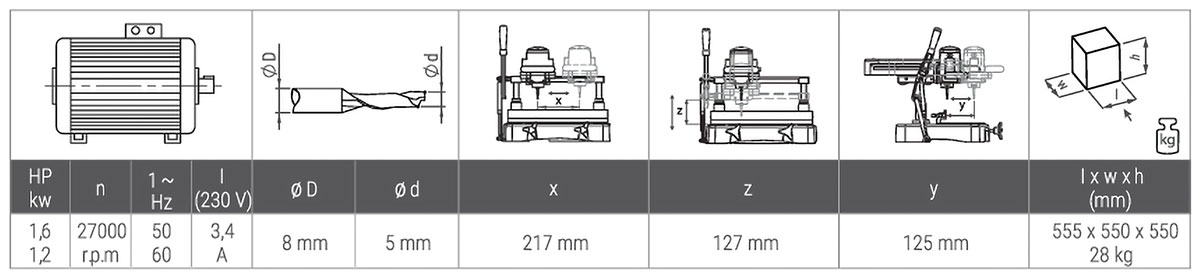

Portable Copy Router MachineSTAR

FEATURES

Used for cutting appropriate slots on aluminum and plastic profiles for mounting locks, grips, hinges, latches and opening channels.

– Copy assembly matching the process<

– Ability to open various channels independently of the copy assembly with profile gauges

– Ease of use and secure operation by ergonomic design

STANDARD EQUIPMENTS

– 5 mm milling cutter (1 pcs)

– Profile gauge (2 pcs)

– Coal (1 se

OPTIONAL EQUIPMENTS

– Stand

– Conveyor

– 110 V motor

– Special copy assembly

STAR

Portable copy router machine

Stanje: 3 kom

Cena sa PDV 760€